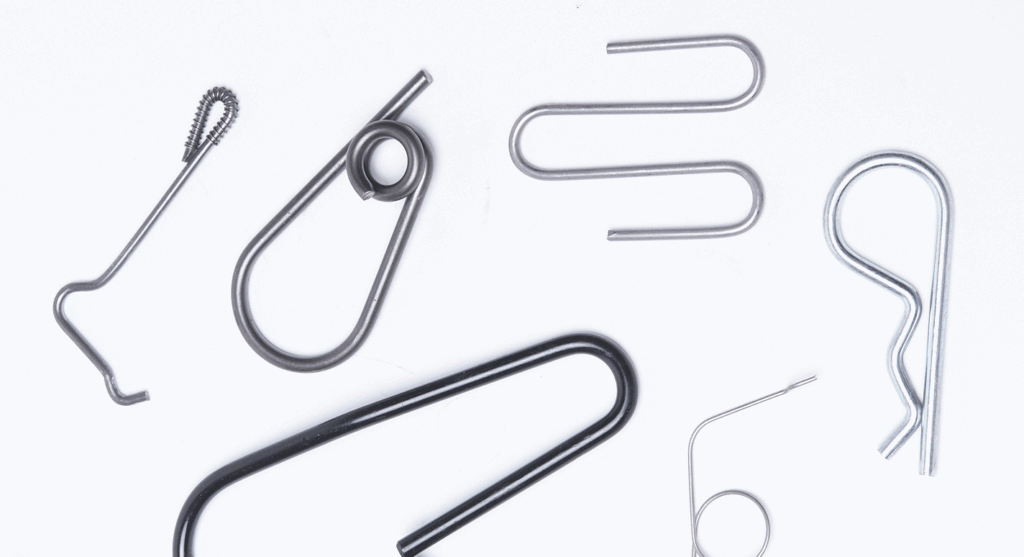

Our three manufacturing plants are equipped with the latest in multi-axis machines to manufacture custom wire forms from 0.010” wire diameter up to 0.312” wire diameter. We also have experienced spring makers and state of the art machinery that enable us to coil and produce custom wire forms up to 0.625”.

Before purchasing custom wire forms, focus on optimizing design for manufacturability by ensuring consistent bend radii (1:1 ratio to wire diameter), minimizing planes, allowing sufficient space between bends, selecting appropriate material tensile strength, and prototyping to validate. These steps reduce costs and improve part quality.

Here are five key tips before buying custom wire forms:

Optimize Bend Radius and Placement: Maintain a 1:1 ratio of bend radius to wire diameter for better consistency and structural integrity and ensure adequate spacing (ideally two wire sizes) between bends to avoid distortion.

Simplify the Design for Manufacturing: Avoid complex bends that cross into multiple planes to lower production complexity and cost.

Select the Right Material: Consider the environmental conditions—such as heat, corrosion, and stress—when choosing materials, noting that lower tensile strength materials are often easier and cheaper to work with.

Prototype and Validate First: Request samples or prototypes to test the fit and function within your application to avoid costly, large-scale production errors.

Choose a Skilled Manufacturer such as Diamond Wire Spring: Select a supplier with in-house design, advanced CNC capabilities, and high-quality assurance to meet strict tolerances and ensure long-term reliability.