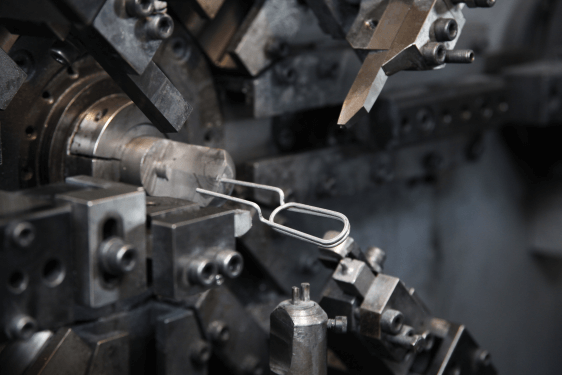

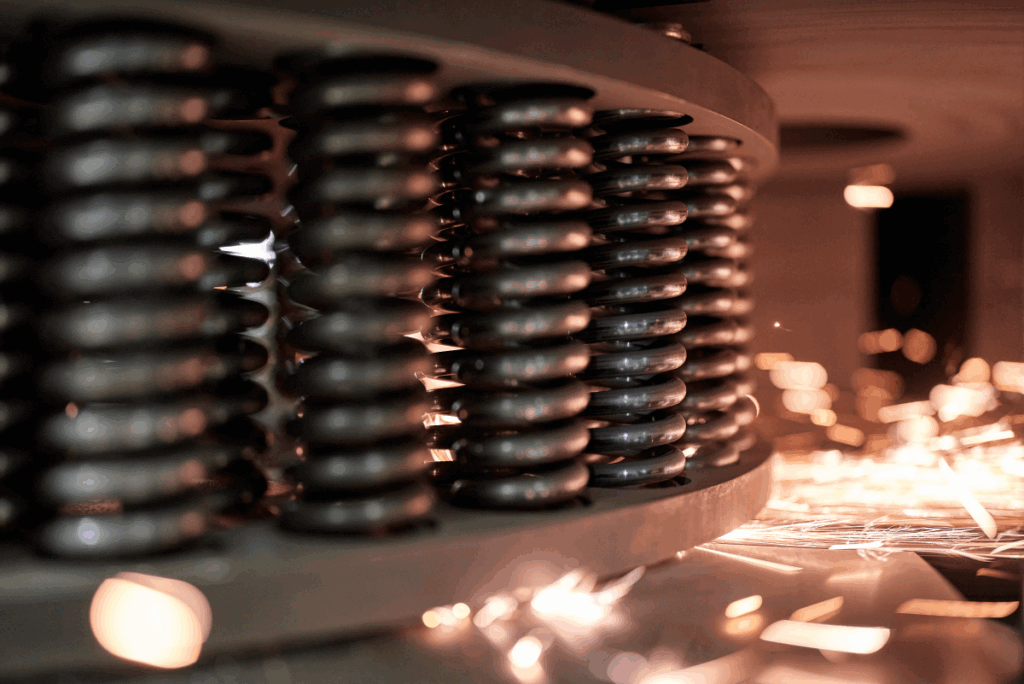

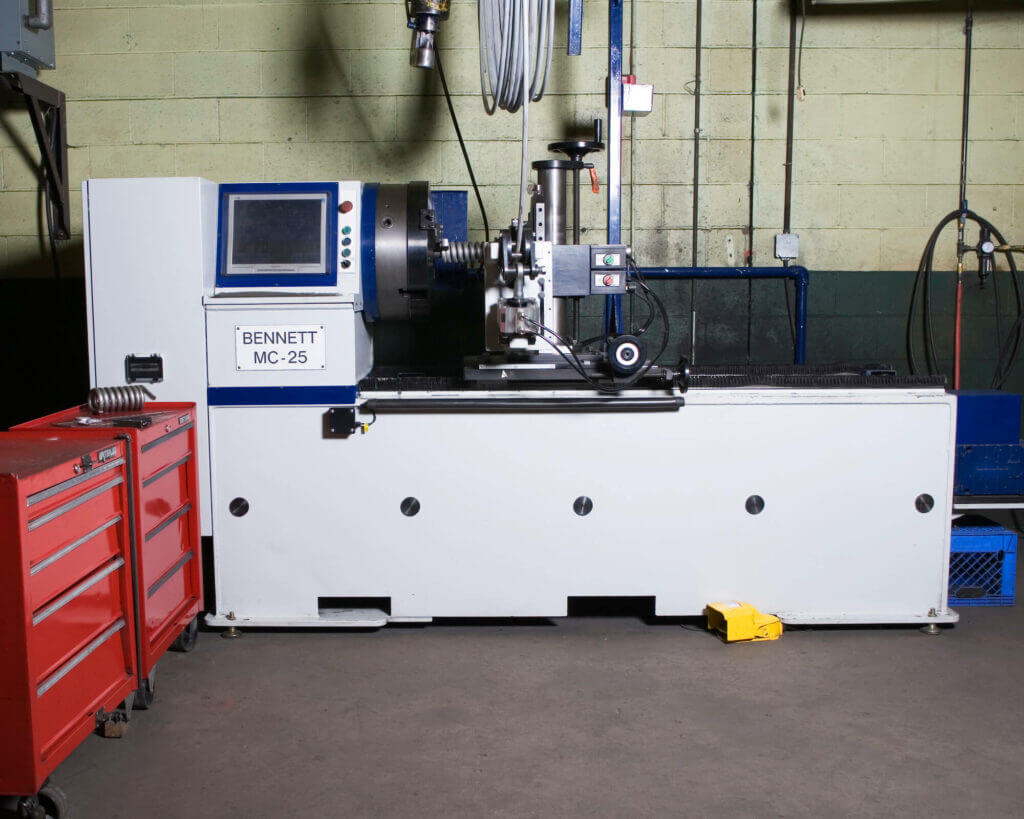

Todays technology enables spring makers the ability to form and bend various wire forms on CNC wire formers and benders. These machines are highly capable of forming and bending various materials in unlimited figurations. Both Diamond Wire Spring plants in South Carolina and Texas have the very latest in spring forming and bending CNC machinery.

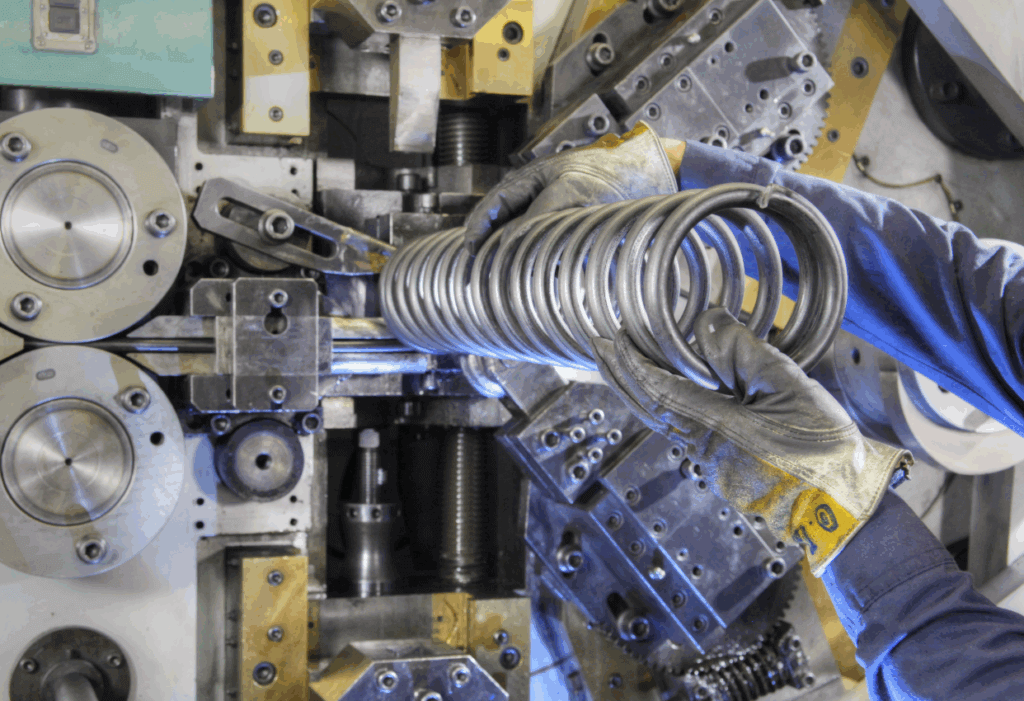

Sometimes springs needs special manual hand made designs or modifications. While Diamond Wire often utilizes advanced multi axis spring coiling machines, we also have a secondary department when a springs needs the human touch.

Wire forms: Wire forms are any shape made out of wire — not just a coil. There are a jillion different kinds of wire forms.

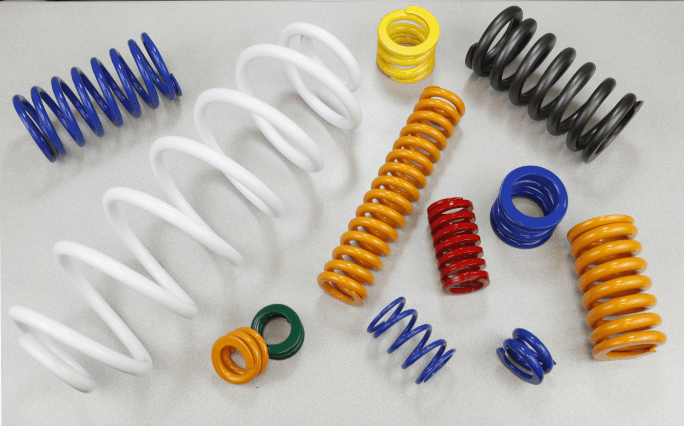

Limited-travel extension springs: Sometimes you’ll want to make an extension spring that only extends so far and then stops. You’ll see these sometimes on screen doors, or farm fencing, these are called draw bar springs:

Extended Hooks

You may want to make an extension spring with extended hooks, like this below.

The best way to do this is to coil the spring as if it were a torsion spring and then bend the ends over to form the extended hooks.

LOOPS AND HOOKS

Loops will work best for most extension springs. Sometimes, though, you’ll want hooks — like when you’ll want to slip the spring onto a pin, for instance.

Making hooks is very simple, once you’ve made loops: all you have to do is cut the end of the wire off so that it doesn’t come all the way around to the body of the spring.

SWIVEL HOOKS

Extension springs are also sometimes made with hooks that are separate from the spring that swivel. The last few end coils would be a conical shape to hold the hook in place.

TORSION SPRING ENDS

Don’t forget that torsion springs come left-handed and right-handed. Be sure to make you request the correct direction.

Torsion Springs start with straight arms. They quite often have one or more bends, to fit within a movement device, tooling, or to hit a stopping point in the final product.

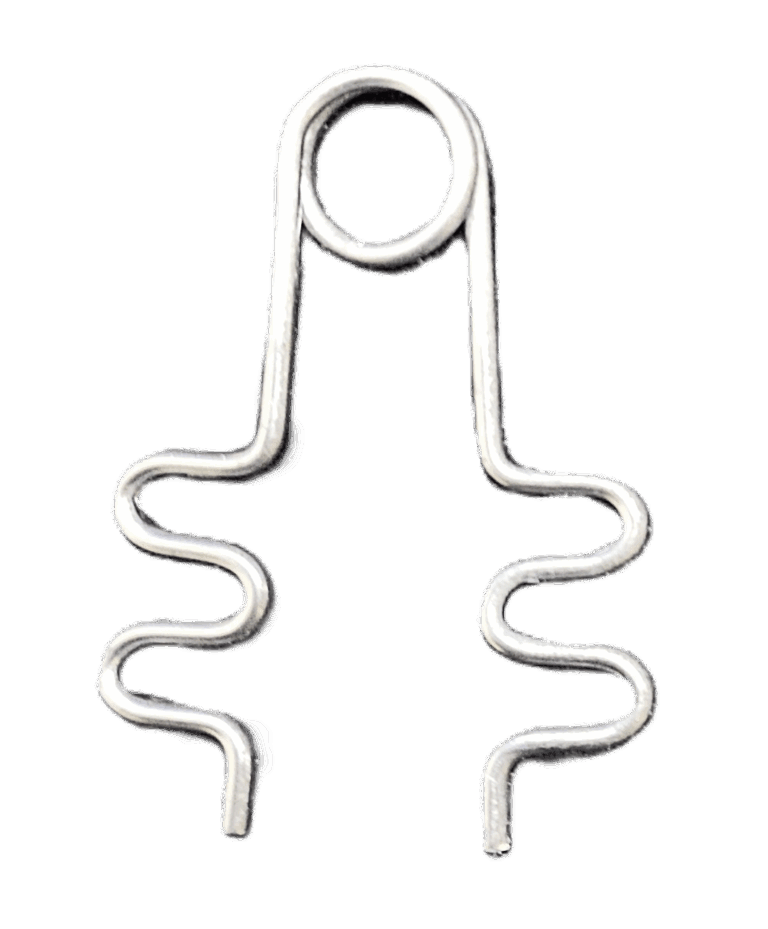

Double torsion springs: You recall how torsion springs can be either left-handed or right-handed? Well, sometimes you’ll want to make a torsion spring that’s both. Such springs are sometimes found on clipboards, and they might look like this.

Making double torsion springs means making some pretty specialized tooling, Depending on the wire size, they can be formed on a CNC machine or a manual lathe.