Spring manufacturing of cold wound springs begins by selecting high quality steel or alloy spring tempered wire per nationally recognized industry standards that match the size and type for the required spring production. Wire can be obtained in a variety of shapes such as square, rectangular and round wire with the latter being the most common.

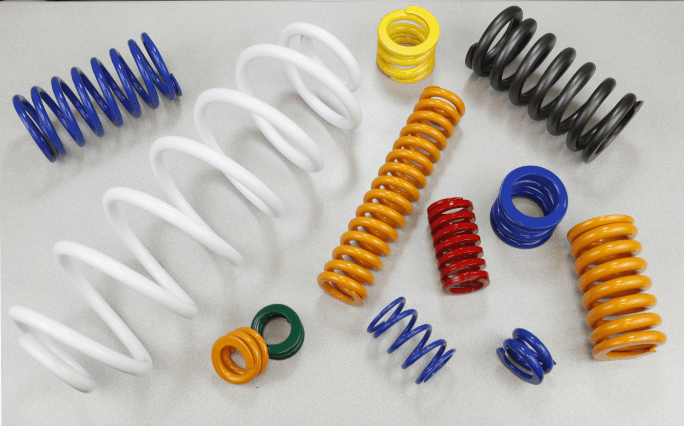

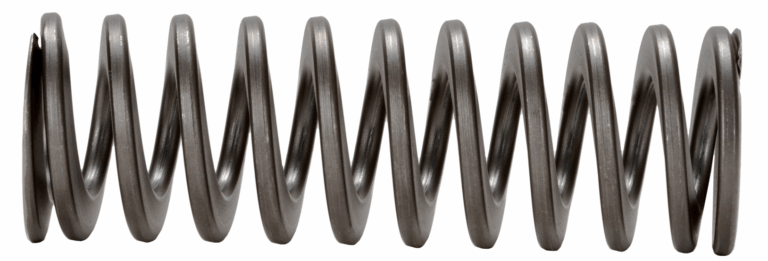

There are several methods of winding the wire to form coils into a spring and the chosen method is based on the type, geometry of the spring, or order quantity. Although there are many shapes that can be formed to make a spring, the most common shape is the cylindrical coiled spring.

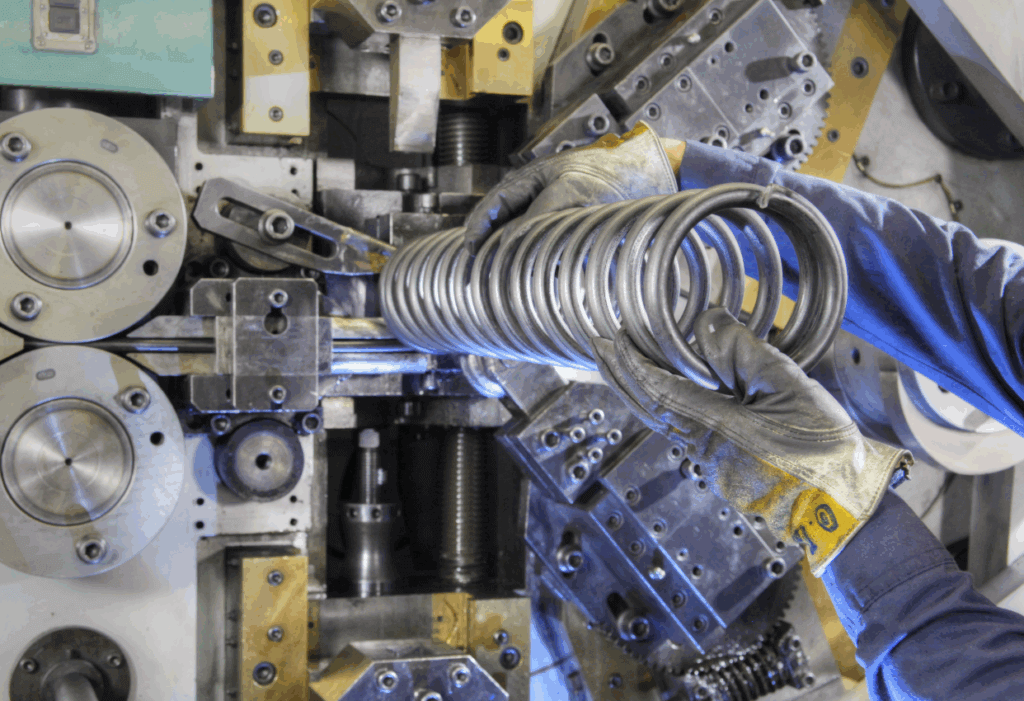

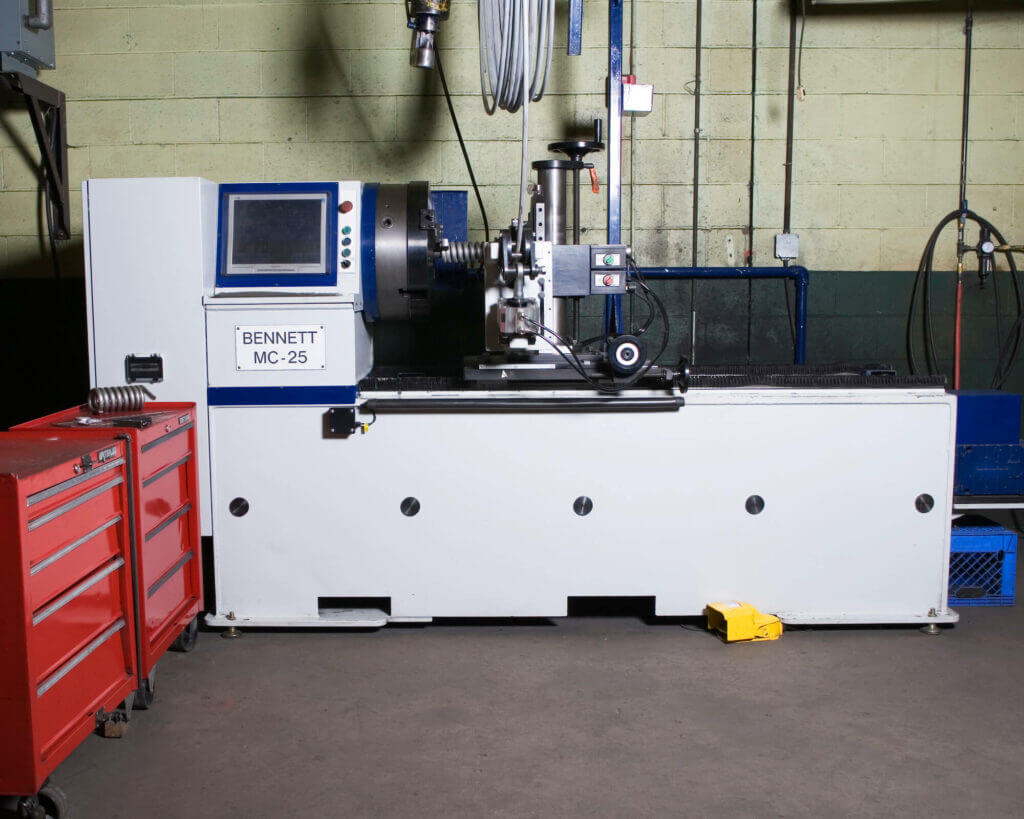

Small lots or one-off prototypes can be produced on a mandrel that is locked into a rotating chuck in either a hand driven powered winding jig or up in an engine lathe based on the size of the wire required and geometry of the spring. The wire is wrapped around the mandrel by a catch on the chuck and a wire guide on the carriage that is either mechanically driven by a feeding mechanism which could be mechanical or computer-controlled to pitch out the coils to obtain the required length. Standard automatic production coilers today are computer-controlled utilizing servo motors for precision manufacturing to produce compression, extension and torsion springs. They have sets of wire feed rollers that pull wire over a de-coiler and push the wire through a series of wire guides. The wire is formed over a static arbor and guided either by a single or dual coil point system to produce the coils. A pitching tool pushes the wire out away from the machine at or near the last coil point creating the helix to obtain the length required.

In a single coil point system the forming of the coils is between the final wire guide the arbor and the coil point whereas with the two coil point system the coils are formed by the final wire guide and the two coil points. In both cases the arbor acts as a shear point along with a cutting knife to shear the wire off from the continuous wire finalizing the making of the spring.

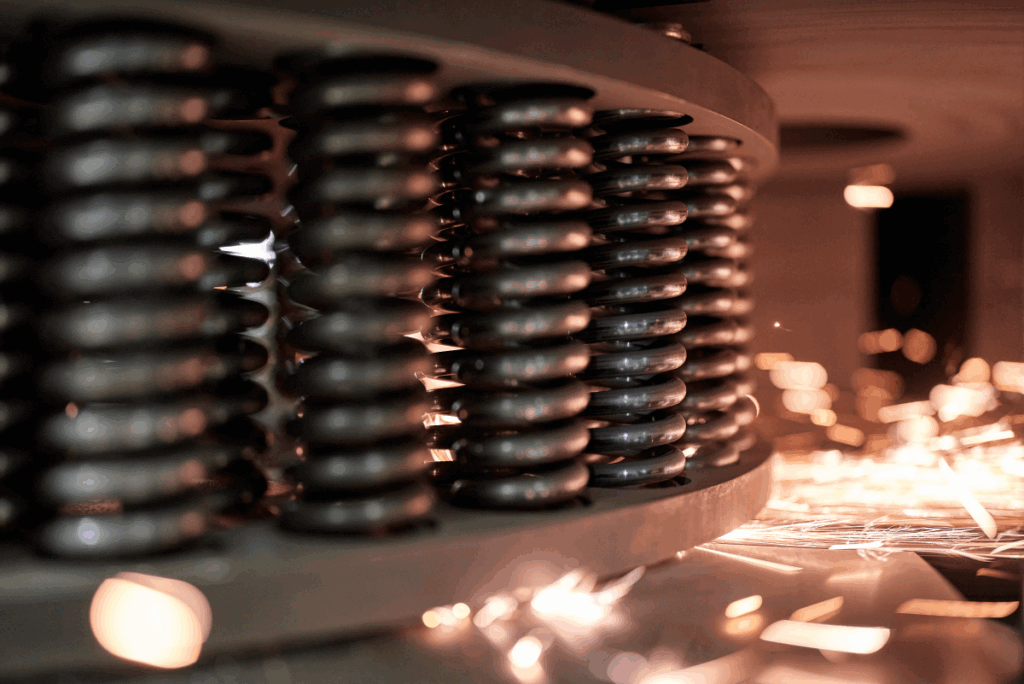

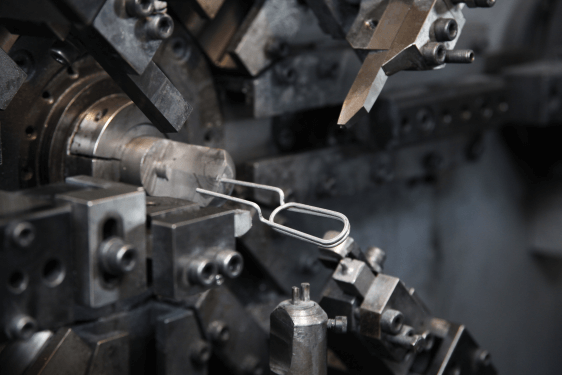

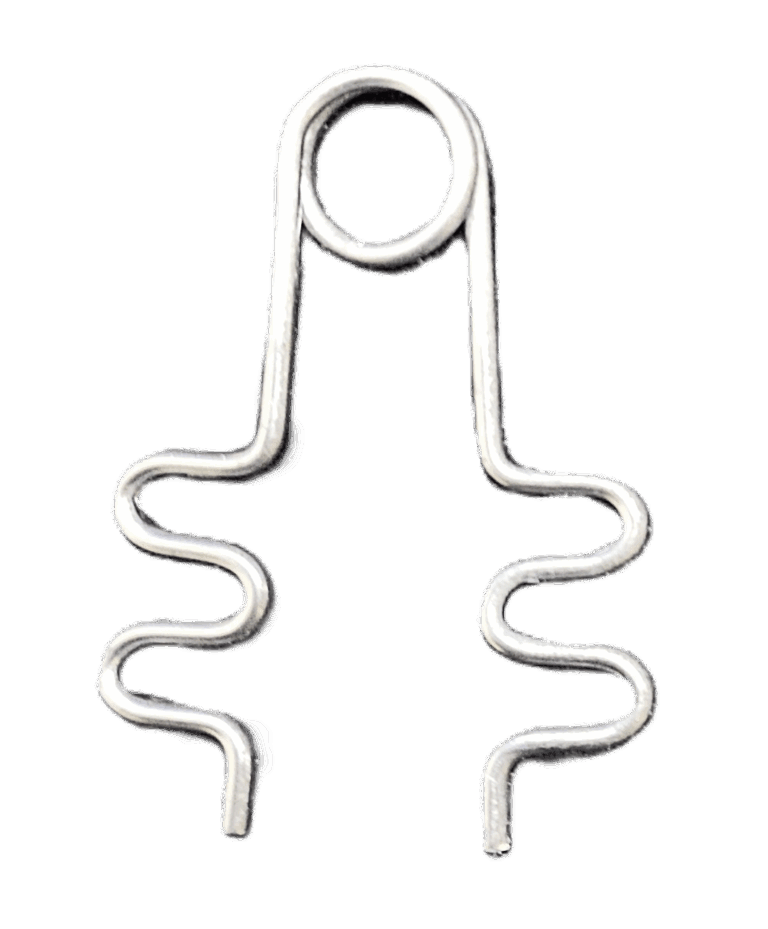

After coiling, parts go through a thermal treatment to relieve the internal forming stresses and or depending on the alloy a precipitation hardening/stress relieving operation. The spring could be complete at this time depending on the requirements or they may need to have secondary operations to complete such as grinding the ends of compression springs, bending out an end coil to form a hook for extension springs, or final bends on arms of torsion springs.

There is of course more specialized forming machinery such as multi-forming spring coilers that could minimize secondary operations on extension and torsion springs or individualized type spring coilers, but each has its own specialized characteristics that we don’t touch on in this brief description of spring manufacture.