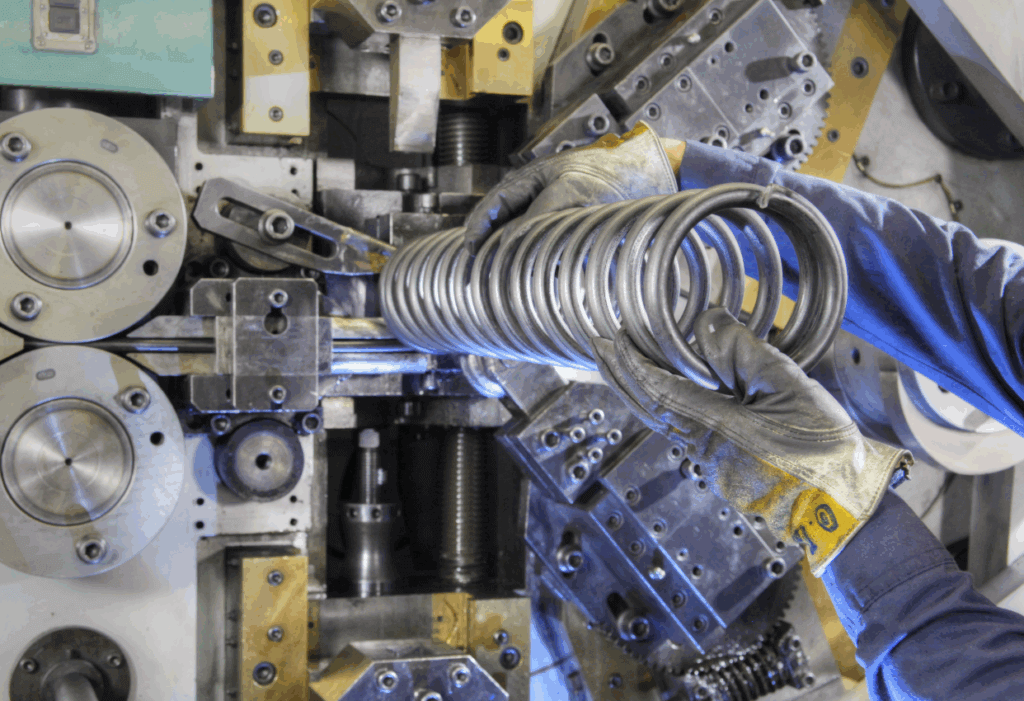

Grinding is required if the spring is to stand square, lay flush with a flat surface, exert a uniform pressure on a flat surface or maintain a more consistent length, enhancing their performance and stability in various applications. Grinding is a relatively slow and expensive process. Therefore, it is important that it be done efficiently.

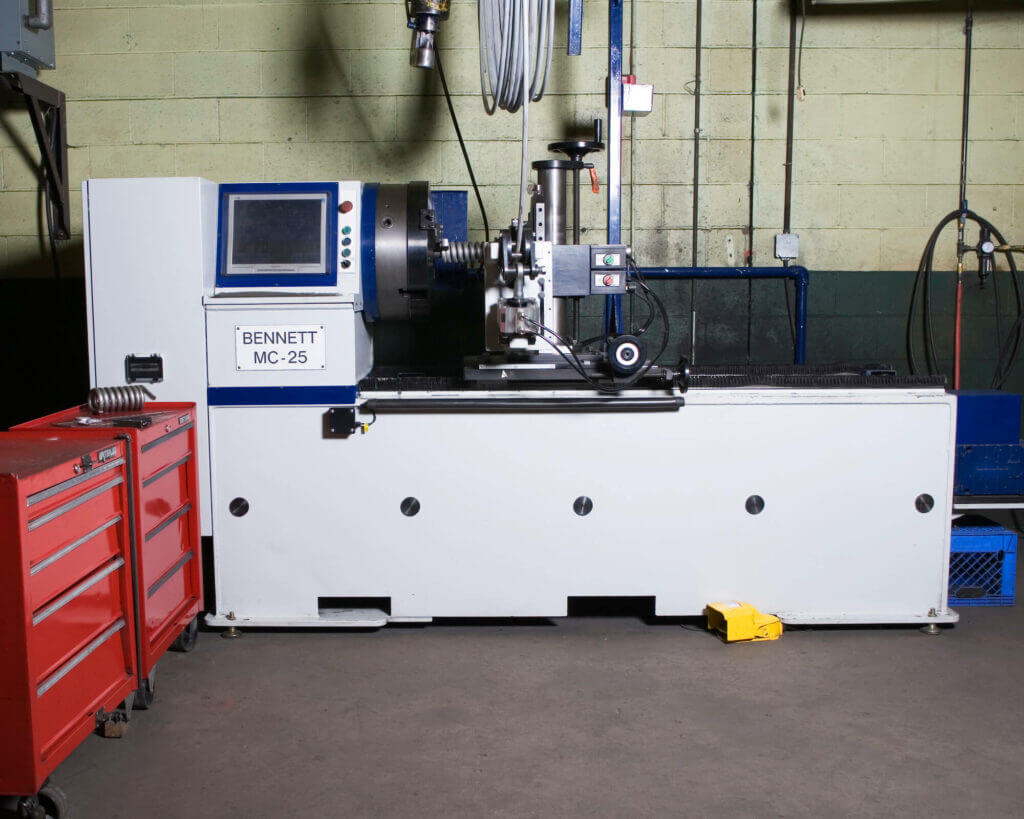

Diamond Wire Spring utilizes all three basic types of grinding machines used for spring end grinding, crash grinders, crush grinders and single end grinders. The first two types, crash and crush, grind both ends of the spring simultaneously and are the most common. We also have a tabletop single end grinder, called upon for larger length springs or special single end applications.

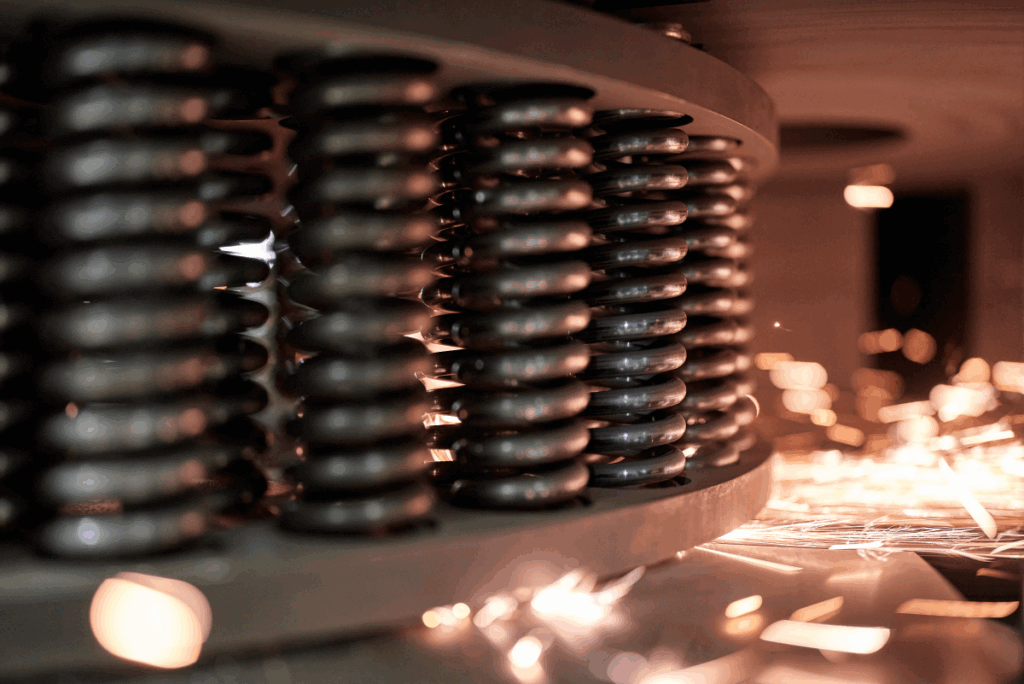

Crash grinders pass the springs between two rotating disc grinding wheels on a rotating table. The grinding wheels are a fixed distance apart from each other and the springs are compressed slightly by entrance guides as they enter the wheels.

In the majority of cases this grinding flat of the ends is done on an automatic grinding machine. These machines consist of a round plate into which bushing are fitted. The bushing inside diameter is of a size so that the springs will fit leaving a small amount of spring protruding top and bottom. The plate then turns slowly round so that the bushing plus springs pass in between either one or two pairs of grinding wheels depending on what type of machine is used. The grinding wheels grind the ends of the springs flat and square and then they drop into a waiting box for inspection when they are thoroughly tested to make sure they comply both dimensionally and in their load requirements.

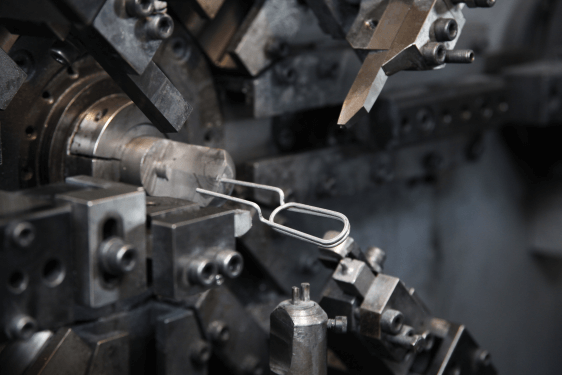

Crush grinders, also known as downfeed grinders, look very much like crash grinders, but grind the springs differently. The grinding wheels are kept flat and parallel to each other. The springs are placed in a rotary carrier and passed between the wheels many times while the top wheel is fed down incrementally, as depicted in the graph. The carriers for downfeed grinders typically run at a faster speed than crash grinders. The grinder will often have two carriers, one that can be loaded while the other is grinding. It is claimed that downfeed grinders can hold tighter tolerances for squareness and free length than crash grinders, but they typically sacrifice speed.

If you’re looking at the end of the spring, the ground surface should look flat, once ground.

The other thing to check is how square your ground ends are. You can do this by setting your spring down next to a carpenter’s square, a machinist’s square, a book, or anything else that stands up straight. Then, holding the bottom end of the spring next to your square, turn the spring around and watch the gap between the square and the top end.

If your spring is perfectly square, there will be no gap as you turn the spring around. A small gap is OK, since the ends of the spring will flatten out under load (Commercial squareness in spring shops is ±3 degrees). Generally 3/4 of the bearing surface is ground and 1/2 of the wire thickness is ground off.