Industrial Spring Manufacturing Process

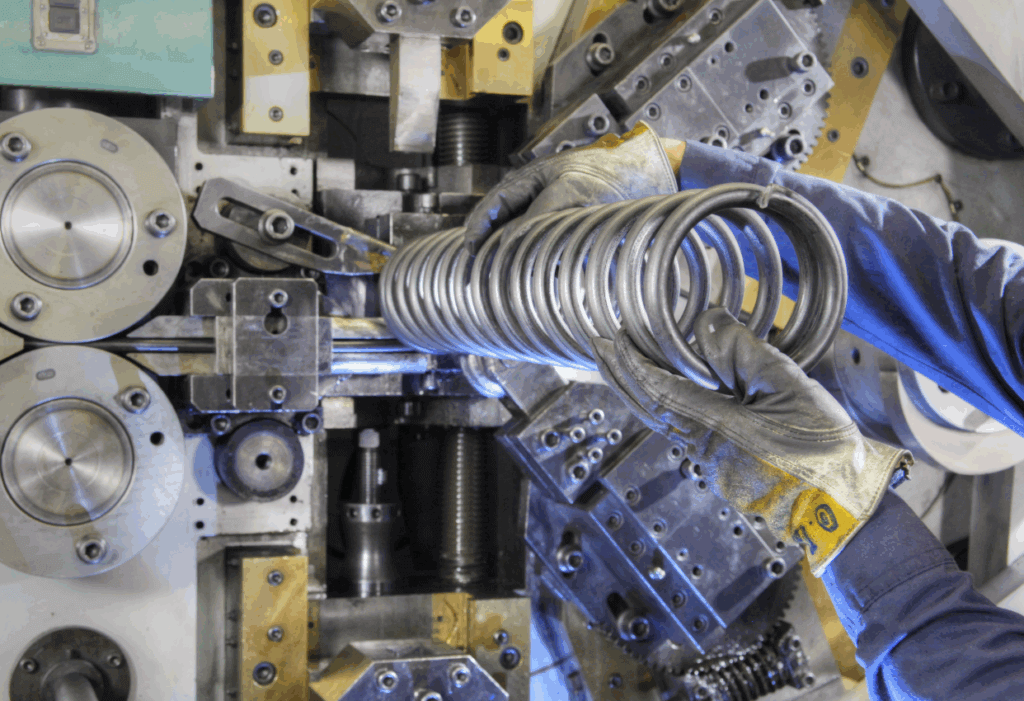

The spring manufacturing and design process starts with you, the customer. Once a Request for Quote (RFQ) is received, along with a print or sample, we promptly work to provide a quote back to you the same day, within a few hours in most cases. RFQs are first checked to see if we can provide a part straight from our Stock Catalog.

Upon submitting a quote, we would point out any deviation at this point, examples being wire size or finish. We may also make any design recommendations. Upon a PO submission, the drawing or specs are reviewed to ensure a good design. All required tolerances, or finishing are listed for manufacturing.

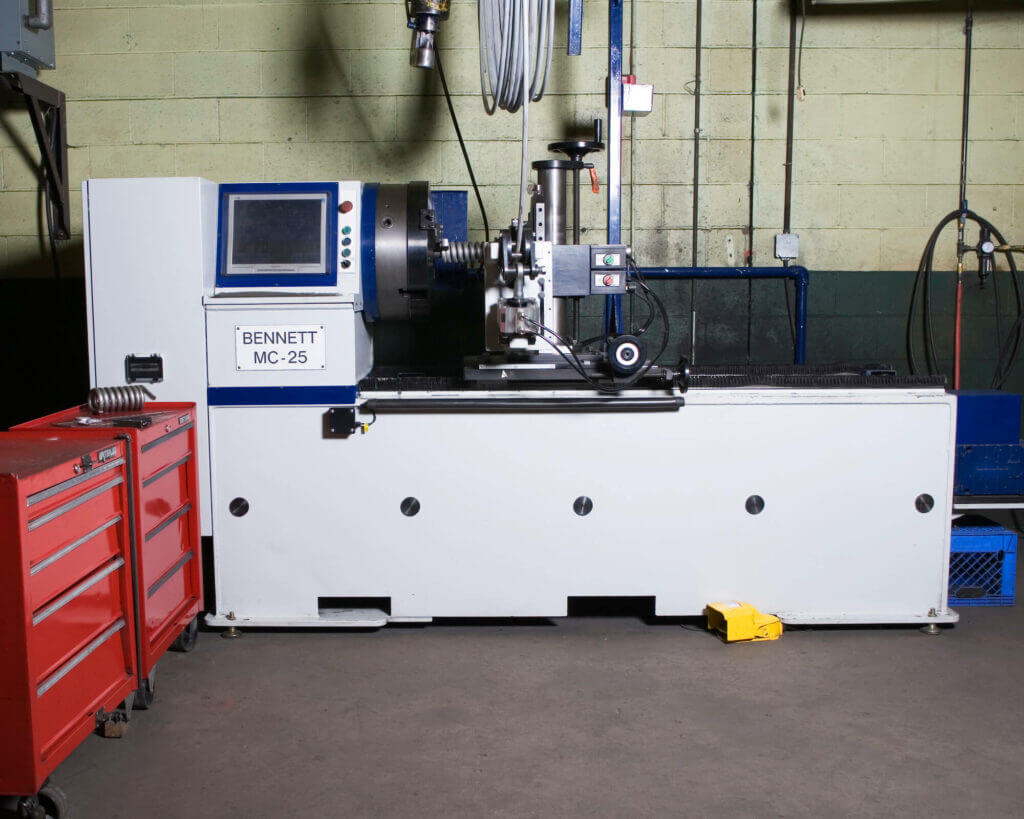

The order is then entered, an acknowledgment is generated back to the customer, a job is released to the shop, to meet your deadline.

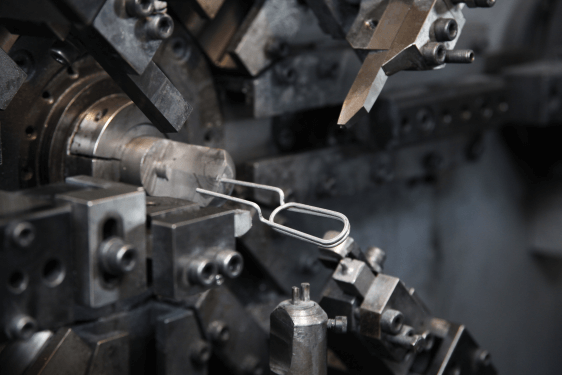

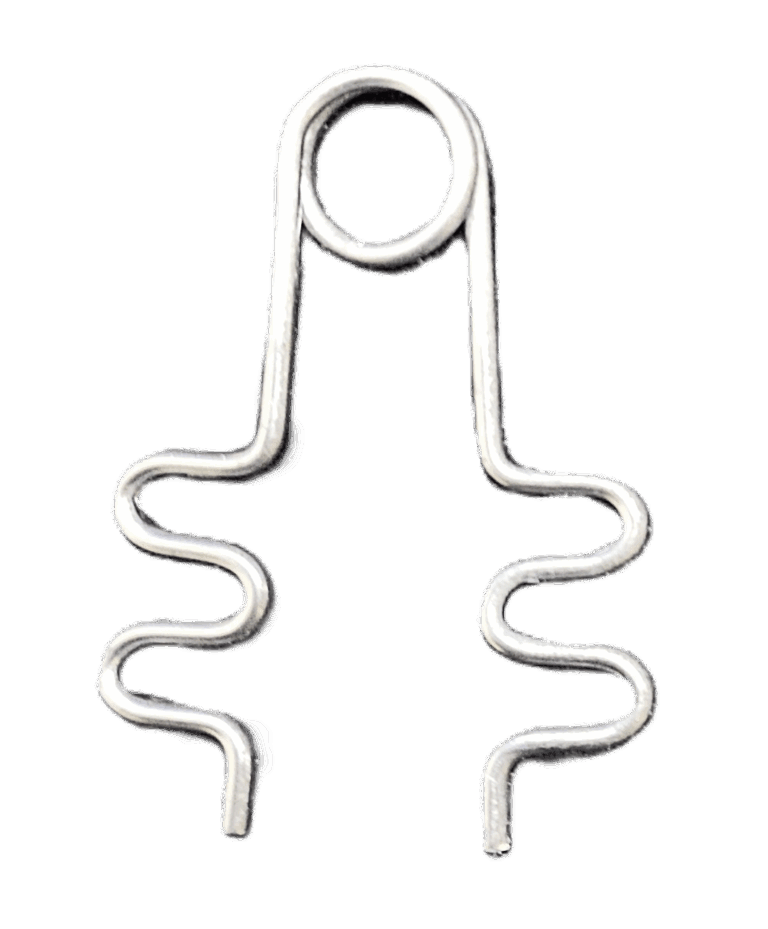

Sometimes customers first want to ensure fit in its intended application. To serve our customers in this area and remove some of the uncertainty from spring design, Diamond Wire Spring offers pre-production runs and prototyping options for a wide range of springs and wire form products. Our prototype services allow you to verify your part’s form, fit, and function. with small lot quantities.

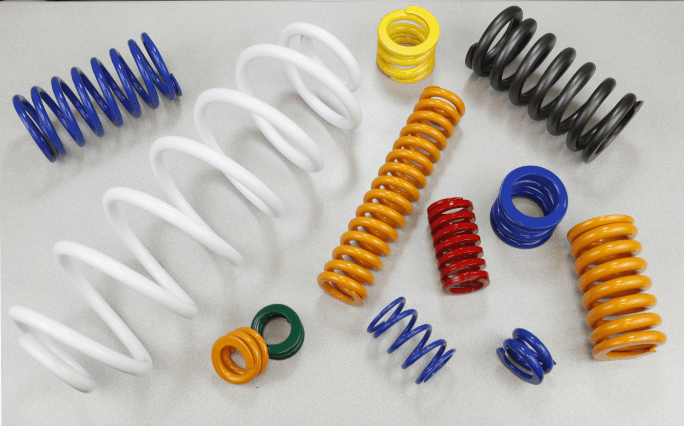

Such capabilities allow us to quickly produce limited quantities of d prototype custom production pieces using the actual geometry and material needed for your application. We can prototype various spring types and configurations. We move quickly to deliver prototype products as quickly as possible because we understand that efficiency is essential to your tight product development deadlines.