Torsion Springs Manufacturer

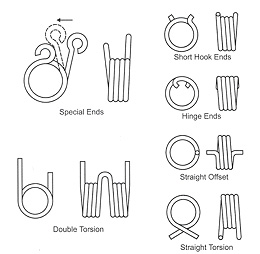

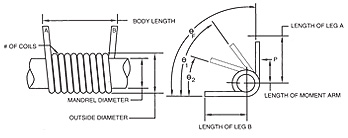

Torsion springs are a type of coil or helical spring used to apply a torque or store rotational energy and subsequently release it. The two most common types are single and double torsion springs.With that being said, Diamond Wire offers a selection of torsion springs with equally lengthed legs, oriented to your prefered unloaded angles.

TORSION SPRING CHARACTERISTICS

Torsion springs are stressed in bending during manufacture. If possible, a torsion spring should always be loaded in a direction that causes the body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring is loaded in a direction that increases body diameter.

Unless there are unfavorable residual stresses in the end bends, Diamond Wire's torsion springs are normally heat-treated at a low temperature to stabilize the end positions rather than fully stress-relieve them. If the direction of loading tends to increase body diameter, our torsion spring maker would typically stress-relieve the springs.

Torsion Spring Applications:

- Clothespins

- Window shades

- Counterbalance mechanisms

- Ratchets

- Hinges and various other machine components

They are also used as couplings between concentric shafts such as in a motor pump assembly. Torsion springs are generally mounted around a shaft or arbor, and must be supported at three or more points.

Contact us today to learn more about our torsion spring and custom offerings, we are here to answer your questions as your torsion springs manufacturer.