Extension Springs

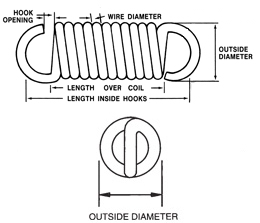

Extension Spring Characteristics

Heavy duty extension springs and tensile springs are typically made with initial tension, which forces the coils to press against each other in the unloaded position. Heavy duty extension springs and tensile springs are typically installed with an initial tension that stretches the spring until the coils are close to separating. After the initial tension has been applied, the extension spring deflects only if it receives a load greater than the initial tension. Heavy duty extension springs and tensile springs have hooks on their ends to attach them to the application. Various hook styles and configurations are available depending on the particular application.

Extension Springs vs Compression Springs

Helical extension springs do not normally have the set removed. Furthermore, unlike compression springs, extension springs do not have a solid stop to prevent overloading. For these reasons, design stresses are generally lower for extension than compression springs. A special type of extension spring, known as a drawbar spring, has a solid stop. It is essentially a compression spring with special hooks.

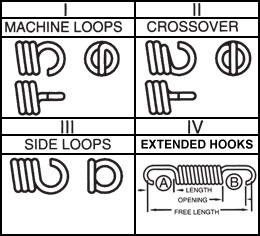

SPRING END TYPES

- Machine Loops

- Crossover

- Side Loops

- Extended Hooks

Materials

- Music Wire

- Stainless Steel

APPLICATIONS

Extension springs, also called tensile springs, are found in many applications, such as:

- Automotive Industry

- Industrial Equipment

- Aerospace & Defense

- Medical Equipment

- Electronics

Diamond Wire Spring company is your source for custom extension springs. Contact us to learn more about our tapered extension spring.

Search Extension Springs

Tell us about the spring you are looking for. We carry a large number of

springs in stock and can also handle most custom spring projects.

Fill in as much information as you know and we will look up the

closest spring(s):